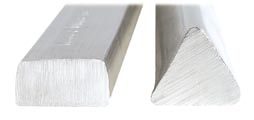

Kester has developed Ultrapure® K100, a low cost lead-free bar solder. Kester K100 is a near eutectic SnCu alloy with controlled metallic dopants to control the grain structure within the solder joint. This improves reliability of the joint and virtually eliminates the occurrence of common defects such as icicling and bridging. The improved grain structure also results in shinier solder joints than traditional lead-free alloy alternatives. Kester K100 compares favorably to low-cost. lead-free alloys of Sn and Cu in terms of wetting and flow characteristics. Kester K100 provides the lowest delivered price to the global market for wave soldering operations. Kester K100 also provides solder joints with no visible shrinkage effects, excellent through-hole penetration and topside fillet, low dissolution of Cu from boards and components into solder pot and low dross rate.